Since it's establishment in 2013, Sharp Laser Component has emerged as a prominent player in the manufacturing industry, specializing in the production of SS/MS sheet metal components and fabrication. With a commitment to excellence and a customer-centric approach, the company offers a comprehensive range of services, including sheet metal fabrication, precision sheet metal parts, customized metal parts, CNC laser cutting, CNC bending, CNC water jet cutting, and CNC HD plasma cutting. Sharp Laser Component has successfully carved a niche for itself by delivering high-quality products and services to a diverse clientele.

At the core of Sharp Laser Component's success lies its state-of-the-art manufacturing facilities. Equipped with advanced machinery and cutting-edge technology, the company ensures precision and efficiency in every aspect of the manufacturing process.

We recognize that the disciplines of quality, health & safety, and environmental management are an integral part of its management function. We have hired a team of highly qualified and experienced professionals. These professionals hold vast experience in this domain, which helps us in rendering the services as per the latest trends of the market. Due to our ethical business policies and transparent dealings, we have earned the trust and faith of our prestigious clients spanning across the country.

Under the Leadership of our mentor Mr. Brijesh Agarwal & Mr. Umesh Agarwal we have been able to win a highly cherished name amongst our customers. Moreover, we are offering with these services under the direction and leadership of a capable staff of professionals that we have hired at our premises.

Why Us ?

State-of-the-Art Manufacturing Facilities

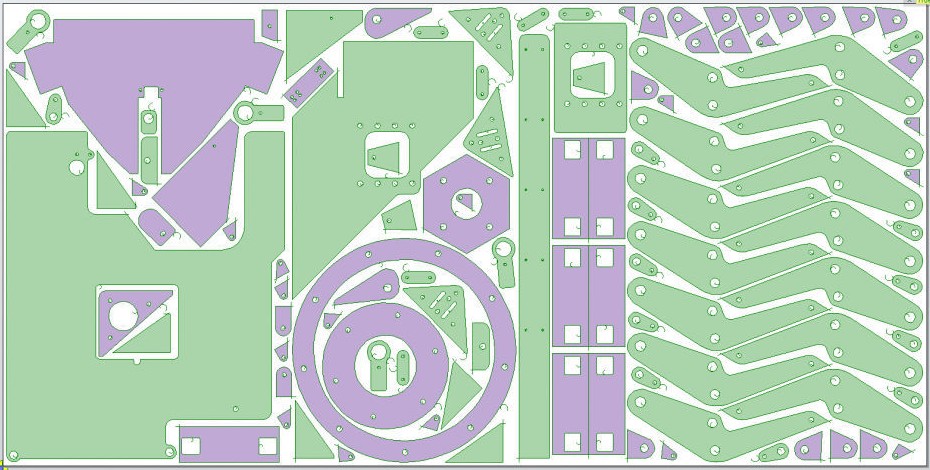

At the core of Sharp Laser Component's success lies its state-of-the-art manufacturing facilities. Equipped with advanced machinery and cutting-edge technology, the company ensures precision and efficiency in every aspect of the manufacturing process. The incorporation of computer numerical control (CNC) systems in laser cutting, bending, water jet cutting, and HD plasma cutting allows for high accuracy, reduced production time, and exceptional repeatability.

Sheet Metal Fabrication Expertise

Sheet metal fabrication is a critical aspect of Sharp Laser Component's operations. The company's team of highly skilled and experienced professionals excels in transforming raw sheet metal into complex and customized components. With expertise in various metals, including stainless steel and mild steel, they can deliver components with precise dimensions, tight tolerances, and excellent surface finishes. Whether it's prototyping or large-scale production, Sharp Laser Component offers flexible solutions tailored to meet the unique requirements of each client.

Advanced Cutting Machineries

We use top class advanced machineries such as TruLaser Series 1000. It provides many technological functions and is already worthwhile, even at low utilization levels thanks to the low investment and operating costs combined with maximum throughput and TRUMPF’s high quality standard. You can perform laser cutting at the push of a button.

Commitment to Quality and Customer Satisfaction

Sharp Laser Component places a strong emphasis on quality control and customer satisfaction. The company adheres to rigorous quality assurance protocols throughout the manufacturing process to ensure that every product leaving its facility meets the highest standards. By incorporating advanced inspection techniques and quality management systems, the company guarantees the reliability, durability, and functionality of its components. Furthermore, Sharp Laser Component's customer-centric approach focuses on understanding the unique requirements of each client. By maintaining open lines of communication and providing tailored solutions, the company builds strong partnerships with its customers, resulting in long-term collaborations and customer loyalty.

Versatility across Materials

One of the major advantages of CNC cutting services is their ability to work with a wide range of materials. Whether it's metals like Mild steel, Aluminium, Copper, Brass, Titanium, Inconel, Duplex, Hastalloy, Tool steel, Hardox, Ceramic, Carbide, Fiberglass frp, Carbon fiber, Glass, Acrylic, Nylon, Polypropylene, Polycarbonate, Pvc, Uhmw, Marble, Tiles, Granite, Stones, or non-metal materials like wood, Foam Rubber, or composites, CNC cutting machines can accommodate them all. The versatility allows businesses across various industries to leverage this technology for their unique cutting requirements. From signage and decorative elements to industrial prototypes and intricate molds, CNC cutting services provide a versatile cutting solution for numerous applications.

About Us

Sharp Laser Component has been providing superior customer support and service for over many years.

- Sheet Metal Fabrication

- Sheet Metal Components

- Precision Sheet Metal Parts

- Customised Metal Parts

- CNC Laser Cutting

- CNC Bending

- CNC Water Jet Cutting

- CNC HD Plasma Cutting

Our Vision & Values

- We are well equipped with latest machines owing to which we offer best products and services.

- We are capable to fulfil large demands of the customers.

- We only offer our clients products which are finished with utmost precision.

- We always advance at everything we do, and every technology we equip.

- Punctuality is never compromised by us.

Factsheet

Key Facts of Sharp Laser Component

| Nature of Business | Manufacturer/ Service Provider |

| Year of Establishment | 2013 |

| No. of Employees | 30 |

| No. of Engineers/ Designers | 08 |

| No. of Production Units | 02 |

| Banker | TJSB Sahakari Bank Ltd |

| Income Tax Registration No. | AABPA9076F |

| Central Sales Tax No. | 27AABPA9076F2ZT |

| Service Location | Bhiwandi, Thane, Mumbai, Navi Mumbai |