Bhiwandi Dapode, Thane – 421302, Maharashtra, India

Your story starts from here

BED SIZE : 1500 x 3000 mm

| Material | Thickness Range |

| Stainless Steel | 0.5 - 20mm |

| Mild Steel | 0.5 - 25mm |

| Aluminium | 0.5 - 20mm |

| Copper | 0.5 - 8mm |

| Brass | 0.5 - 8mm |

| Titanium | 0.5 - 3.5mm |

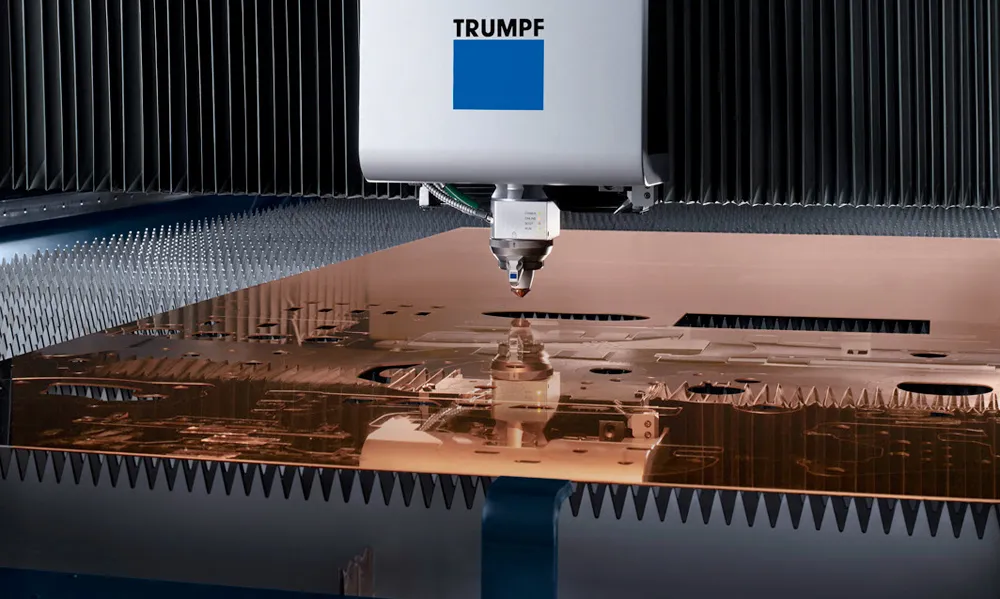

Our CNC laser cutting service is powered by the TRUMPF TruLaser Fiber 4kW machine, a leader in the industry known for unmatched performance, reliability, and precision. Equipped with advanced automation and high-speed cutting capabilities, our laser setup allows us to handle both high-volume production and custom fabrication with equal efficiency. This setup enables minimal material wastage, faster turnaround times, and superior repeatability, making it ideal for demanding industries where quality and precision are non-negotiable.

Your story starts from here