Bhiwandi Dapode, Thane – 421302, Maharashtra, India

Your story starts from here

BED SIZE : 2000 x 3000 mm

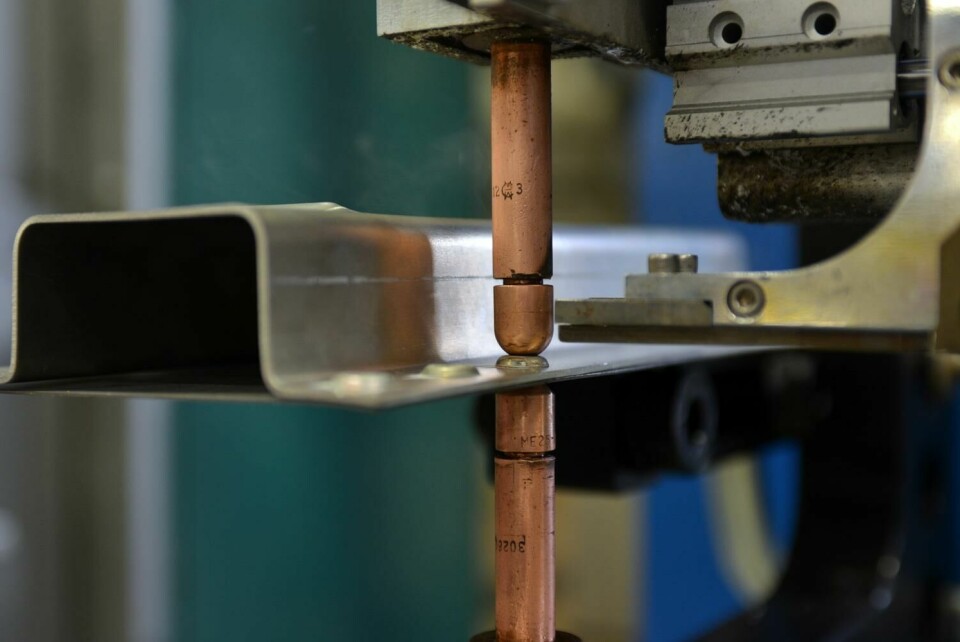

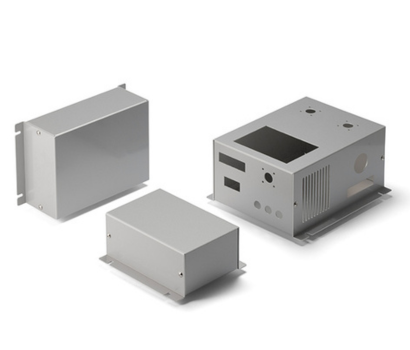

We offer two primary welding processes, operated by a team of skilled and experienced welders, to provide the best solution for your project:

Our welding division combines advanced technology with skilled craftsmanship to deliver durable, high-quality joints for a variety of applications. We offer two primary welding processes, each suited to specific project requirements, ensuring both structural integrity and aesthetic precision.

Your story starts from here